Stellar Heavy offers a comprehensive range of aftermarket MPS Cedar Rapids jaw, cone and impact crusher parts. Below is an overview of the available parts categorized by MPS Cedar Rapids crusher type:

With nearly 200 years of combined experience in jaw crusher manufacturing, Terex MPS Cedar Rapids provides rugged and field-proven designs.

Our aftermarket parts for Cedar Rapids jaw crushers cover a wide range of models, ensuring compatibility and reliability:

Modular Jaw Crushers: MJ42, MJ47, MJ55, MJ400R

Portable Jaw Crushers: CRJ3042, CRJ3255

Static Jaw Crushers: JS4552, JS3750, JS3042, TJ2440, JW42, JW55

Cedarapids cone crushers are known for their production efficiency and advanced features such as hydraulic tramp iron relief systems, automation, and telematics.

Our aftermarket parts support the following models:

Modular Cone Crushers: MC1000, MC1150, MC320, MC1300, MC380X, MC450X

Portable Cone Crushers: CRC1350, CRC1150, CRC1150S, CRC320, CRC380X, CRC380XHLS, CRC420, CRC450X

TC Series: TC1000, TC1300, TC1150, TC150

TG Series: TG120, TG220, TG320, TG420, TG820, TG1020

TGS Series: TGS120, TGS220, TGS320, TGS420

MVPX Series: MVP380X, MVP450X, MVP550X

Cedarapids Horizontal Shaft Impactors (HSI) are engineered for high tonnage material processing, excellent particle shape control, and adaptability to various materials, including recycled feed. Our aftermarket parts support these models:

Our aftermarket parts support the following models:

Modular VSI Crushers: MV2000, MV3000

Portable HSI Crushers: CRH1111R, CRH1113R, CRH1316

Portable VSI Crushers: CRV2000, CRV2050, CRV2350

Static VSI Crushers: TXC1000, TXC1300, TXC2000, TI4143, IP1313, IP1316, IP1516

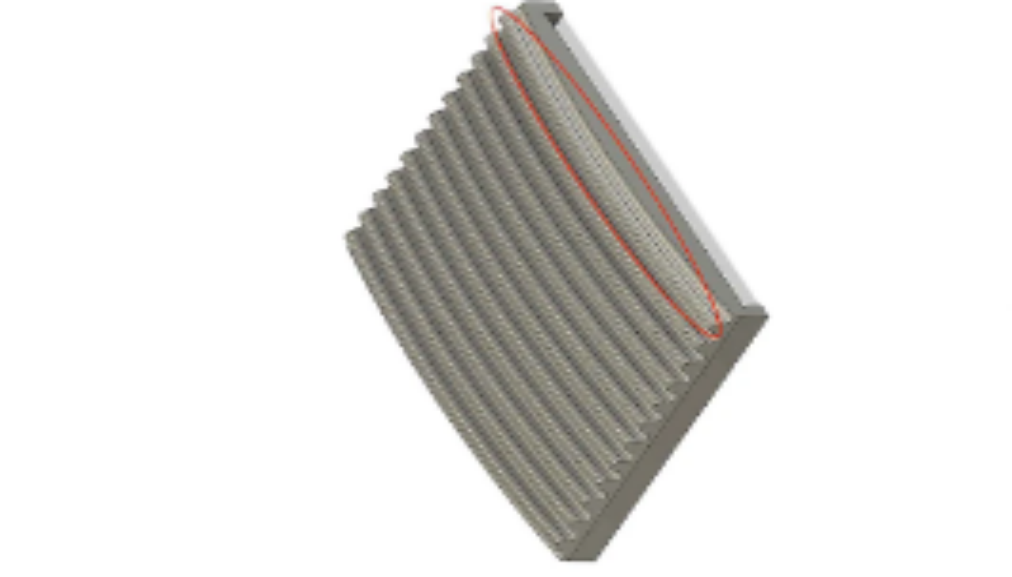

| Mn | Cr | C | Si | |

| Mn13Cr2 | 12-15 | 1.7-2.2 | 1.15-1.25 | 0.3-0.8 |

| Mn18Cr2 | 17-19 | 1.8-2.2 | 1.15-1.3 | 0.3-0.8 |

| Mn22Cr2 | 21-23 | 1.8-2.2 | 1.1-1.4 | 0.3-0.8 |

Click on the link below to check whether we have the parts you need! Our Crusher Parts are listed in the table but are not limited.

FEELING OVERWHELMED? Just toss your crusher parts purchase order to our sales representative! We 24/7 ONLINE committed to getting you the best offer at lightning speed.

| Sample | 202316127-2-2 | ||||||

| Alloy | FE_500 | Mode | Normalized Element Concentrations | 28.06.2023 06:14:04 | |||

| Fe(%) | C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | |

| 1 | 78.1 | 1.25 | 0.658 | 18 | 0.0487 | <0.0013 | 1.82 |

| 2 | 78.2 | 2.25 | 0.666 | 17.8 | 0.0492 | <0.0014 | 1.83 |

| 3 | 78.3 | 3.25 | 0.666 | 17.8 | 0.0501 | 0.0025 | 1.82 |

| Ø | 78.2 | 4.25 | 0.663 | 17.9 | 0.0494 | 0.0017 | 1.82 |

| Mo(%) | Ni(%) | Ai(%) | Co(%) | Cu(%) | Nb(%) | Ti(%) | |

| 1 | <0.0032 | 0.035 | <0.0050 | 0.0055 | 0.0619 | 0.019 | 0.0164 |

| 2 | <0.0046 | 0.035 | 0.0052 | 0.0059 | 0.0616 | 0.0184 | 0.0166 |

| 3 | <0.0041 | 0.035 | 0.005 | 0.0052 | 0.0618 | 0.0176 | 0.0176 |

| Ø | <0.0039 | 0.035 | 0.0051 | 0.0059 | 0.0618 | 0.0184 | 0.0169 |

As a professional crusher parts manufacturer , we are committed to providing top-notch crusher wear parts and spare parts that suitable for Metso, Sanvik, Terex, and other leading crusher wear parts.

*Note: The names of manufacturers, part numbers, model numbers, images, and descriptions are employed solely for reference and identification purposes. These elements are the intellectual property of their respective machine manufacturers. All parts provided by Stellar Heavy are manufactured and warranted by Stellar Heavy itself, independent of the Original Equipment Manufacturer (OEM). It is important to note that Stellar Heavy has no affiliation with the OEM and does not intend to create any impression of such association.

*Note: The names of manufacturers, part numbers, model numbers, images, and descriptions are employed solely for reference and identification purposes. These elements are the intellectual property of their respective machine manufacturers. All parts provided by Stellar Heavy are manufactured and warranted by Stellar Heavy itself, independent of the Original Equipment Manufacturer (OEM). It is important to note that Stellar Heavy has no affiliation with the OEM and does not intend to create any impression of such association.